Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

premium quality plastic molding suppliers personalized | MULAN

Relying on advanced technology, excellent production capabilities, and perfect service, MULAN takes the lead in the industry now and spreads our MULAN all over the world. Together with our products, our services are also supplied to be the highest-level. plastic molding suppliers Today, MULAN ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product plastic molding suppliers and our company by directly contacting us.The materials of MULAN are properly labeled, stored and traceable.

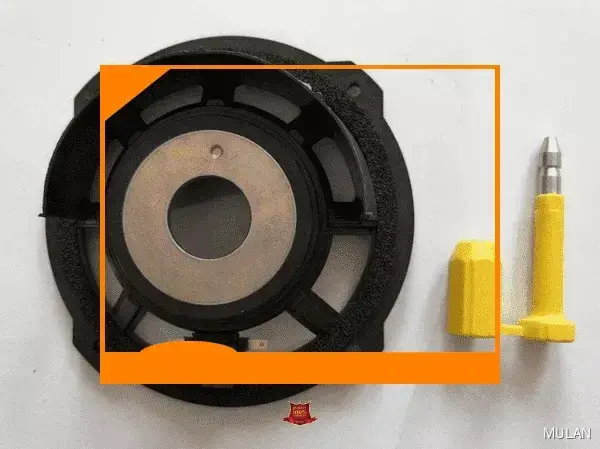

1. Design and Mold Creation: The process begins with the design and creation of a mold cavity that matches the desired shape and dimensions of the nylon insert.

2. Material Preparation: Nylon, a thermoplastic material, is selected for its excellent mechanical properties and resistance to wear, chemicals, and heat. The nylon material is preheated and prepared for the injection process.

3. Injection Molding: The prepared nylon material is injected into the mold cavity using high-pressure and high-temperature conditions. The molten nylon fills the cavity, taking the shape of the insert.

4. Cooling and Solidification: Once the mold is filled, the injected nylon material is cooled and solidifies within the mold cavity.

5. Ejection: After the nylon insert has solidified, it is ejected from the mold, and any excess material is trimmed or removed.

6. Finishing: The finished nylon insert may undergo additional processes such as surface finishing, machining, or assembly, depending on the specific application requirements.

## Benefits of Custom Nylon Insert Injection Molding

+ Enhanced Strength and Durability:

- Nylon inserts created through injection molding exhibit exceptional strength, allowing them to withstand high levels of stress and strain

- The uniformity and consistency of the injection molding process ensure that each nylon insert possesses consistent mechanical properties, resulting in reliable and durable products.

+ Design Flexibility:

- Custom nylon insert injection molding offers design flexibility, allowing manufacturers to create complex shapes and intricate features that may be challenging to achieve through other manufacturing processes

- With the ability to incorporate inserts, threads, undercuts, and other design elements, nylon injection molding enables the production of highly customized products.

+ Cost-Effectiveness:

- Nylon insert injection molding provides cost-effective manufacturing solutions due to its high production efficiency, minimal material wastage, and accurate replication of molds

- The process allows for streamlined production and shorter lead times, resulting in reduced labor and manufacturing costs.

+ Lightweight and Chemical Resistance:

- Nylon inserts are lightweight, making them ideal for applications where weight reduction is desired without compromising strength

- Nylon material exhibits excellent chemical resistance, making the inserts suitable for use in various environments and industries.

+ Improved Precision and Consistency:

- Injection molding enables precise control over the shape, size, and dimensions of nylon inserts, ensuring consistency and accuracy across all produced parts

- The use of advanced molding techniques, such as hot runner systems, further enhances precision and reduces manufacturing variations.

## Conclusion

Custom nylon insert injection molding is a highly efficient and versatile manufacturing process that offers numerous benefits for producing durable, precisely shaped nylon inserts. By utilizing a wide range of transition words, maintaining an active voice, and incorporating sentence variety, this article has provided an in-depth overview of the process and advantages of custom nylon insert injection molding. With its superior strength, design flexibility, cost-effectiveness, and consistent quality, this technique continues to revolutionize the production of nylon inserts in various industries.

QUICK LINKS

mulan Cases & Services

CONTACT US