Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

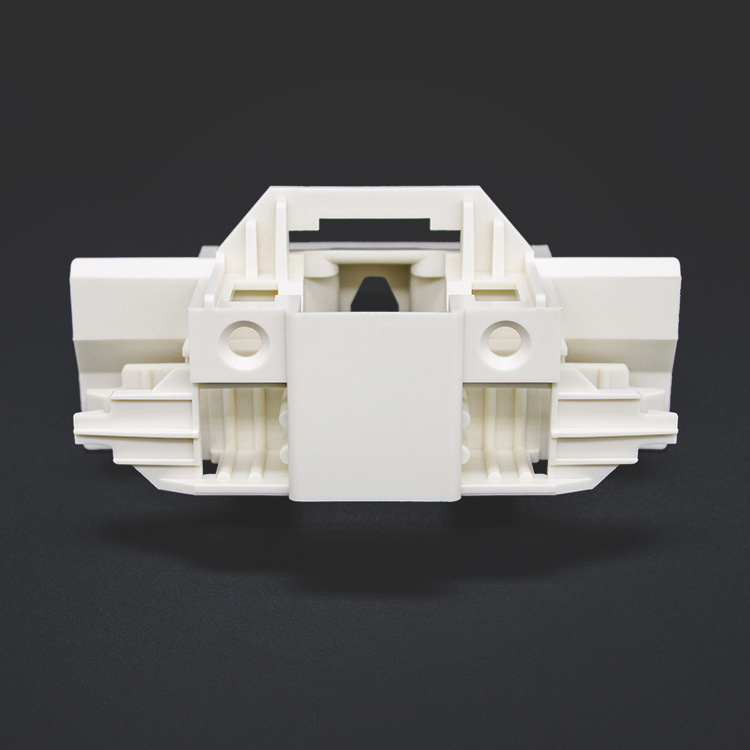

compression molding components | MULAN

Since established, MULAN aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product compression molding components or our company, just contact us.

Looking for the most appropriate forging?? You are at the right place. MULAN brings you a widest range of forging equipment by authentic suppliers and manufactures from across the globe. A reliable forging is of great importance as it is used in various purpose. Forging involves shaping of dense metal by compression with a use of hammer forger. We provide a complete range of different forging specially designed to meet modern industrial needs. Forging are used widely by a range of different industrial sectors for material handling and manufacturing processes. Forging is one of the most important required nowadays due its beneficial outcomes. MULAN is leading platform bridging millions of traders with its exquisite quality controlling and unmatchable product sustenance. We welcome you to explore our range of forging equipment to meet your manufacturing deadlines effortlessly in order to increase productivity and profitability. Take a look at one of the best collection of forging exclusively for you.

What are the benefits of MULAN compression molding components ?

Find the finest quality Forging Molds only at MULAN powered by world class manufacturers and suppliers across the globe. We offer you a wide range of forging molds to meet your diverse requirement cost-effectively. Forging is one of the most reliable and precise manufacturing process. This process can be used for manufacture components that are mainly used in heavy duty industrial appliances. Forging equipment are widely used in different industries in their manufacturing processes making it precise and cost-effective. Forging uses thermal and mechanical energy to transform and use it in the manufacturing process. MULAN is unique b2b platform connecting millions of buyers and suppliers with its exquisite quality controlling and a comprehensive range of products. Forging molds are made with top quality raw material ensuring long lasting life same and durability.

What are pros and cons of Injection Molding Parts vs. CNC Machining Parts ?

Fabrication is a term that is widely used for a process that shapes, molds or cuts, the material of metal into a final product. Stock components of metal, like metal rods, metal bars, and sheet metal, are widely available in an assortment of dimensional and material specifications. Moreover, most shops of fabrication can make products of metal in a broad variety of sizes and shapes. Nonetheless, when the makers need a unique metal product or non-standard component, custom fabrication services can offer both production and unique metal product assistance for these built-to-order parts. Custom Fabrication includes prototyping, design, development, fabrication, metal cutting, welding, electronics, assembly, programming, and testing. Are you looking for custom fabrication? Custom fabrication simply means that different people can offer you the solutions tailored to your needs. So, if you’re searching for Custom Fabrication Services manufacturers and suppliers, MULAN brings Custom Fabrication Services manufacturers and wholesalers close to you. Each Custom Fabrication Services listed above are subjected to inspection to make sure they are ready for trade. If you’re interested in buying Custom Fabrication Services, use the above list to discover the best wholesalers and manufacturers relating to Custom Fabrication Services.

How is a compression molding components made?

Looking for the most appropriate Compression Molds?? You are at the right place. MULAN brings you the widest range of Compression Molds by official suppliers and manufacturers from across the globe. Compression molds are widely used by a wide range of industries including automobile, mechanical, and electronics products. Compression molds are used to compress products in the molds for precise manufacturing process. This process is cost effective and environmental friendly. It used matched metal molds that is closed mold manufacturing process. This process is nowadays being widely adopted by various automobile industries. MULAN is hub of traders across the globe connecting buyers, suppliers and manufacturers with its exquisite quality controlling, product definition, stability and strength. Compression molds at MULAN are prepared with world class raw material for increase durability and support.

How can I choose a compression molding components manufacturers ?

在加工白大理石的过程中,往往会产生很多不用的荒料,边角余料,你知道这些边角余料都去哪里了吗?都丢了吗?不,当然不是!那样就太浪费了呀,而且还不环保。其实,这些边角余料的用途也是十分广泛的。 可以切成不同形状小规格的面砖,做成走廊、花台、卫生间这些小场合的贴面,既经久耐用,整齐美观,还可以当成小朋友的花色游戏场所。 还可以利用大理石本身的自然形体,镶铺室内外地面或者公园走道,根据品种和颜色的不同,结合色调搭配,拼接成圆形、弧形、动植物等生动形象的图案后使用,更显情趣、美观宜人。 其中最广泛的还是用于生产拼花面板。拼花是将不同花色的小面砖,粘结成大规格的板材。拼花的价值也是跟制作的技艺有关联的,若拼花得宜,粘接得当,其价值不逊于正品(大规格)板材。 白大理石荒料也经常被用于制作电气绝缘材料。制成电闸板、灯开关、开关柜等,是电力工业不可缺少的材料之一,其产品相当畅销。 最精致的作用还是用来制成小工艺品和 小日用品。用边角余料制作台灯座、台历板、笔筒、砚台、镇尺、彩画屏幕以及各种门、桌拉手等,雅致美观。给人类生活带来了很多的便利和价值。 佛山MoCo Marble Tiles发展有限公司,专业做大理石开采、加工和深加,每年开采荒料200万m³,年产大理石工艺品约50万件,每年的白大理石荒料资源利用率都达90%,其出产的产品除了销往全国各地,还远销海外,口碑声名远扬,越来越多的厂家都在这里进行加工和采购。

QUICK LINKS

mulan Cases & Services

CONTACT US