Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

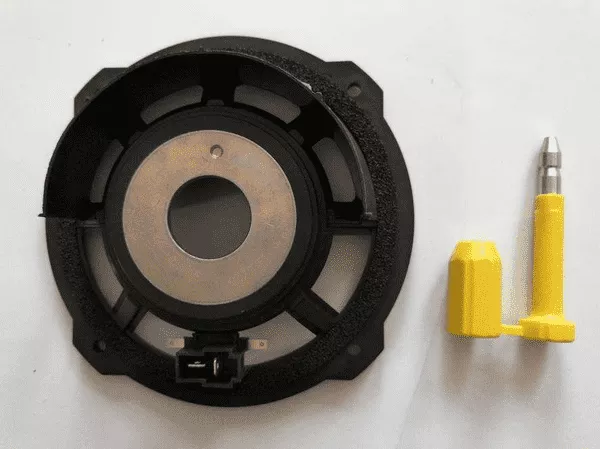

How To Own insert injection molding parts For Free

Since established, MULAN aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product insert injection molding parts or our company, just contact us.

www.china-plasticparts.com offers you one stop solution to get the best coating services. We feature a broad range of coating services. These machines are designed and assembled by highly professional technicians using the best component to provide unmatchable performance and cost-saving. Coating services are used by various industries for the purposes corrosion resistance, preventing perishing and increasing product life. It allows you to get more protection, performance and customization of different products and parts. Coating services offered by MULAN are the most reliable due to usage of high quality products. MULAN is leading platform connecting millions of traders with its exquisite quality controlling and unmatchable product support. By the help cutting edge coating services you can extend the life of your crucial components our coating services is available for all type of product shape and sizes. We welcome you to explore our range of coating services presented with advance engineering exclusively designed for you.

What are the benefits of MULAN insert injection molding parts ?

Fabrication is a term that is widely used for a process that shapes, molds or cuts, the material of metal into a final product. Stock components of metal, like metal rods, metal bars, and sheet metal, are widely available in an assortment of dimensional and material specifications. Moreover, most shops of fabrication can make products of metal in a broad variety of sizes and shapes. Nonetheless, when the makers need a unique metal product or non-standard component, custom fabrication services can offer both production and unique metal product assistance for these built-to-order parts. Custom Fabrication includes prototyping, design, development, fabrication, metal cutting, welding, electronics, assembly, programming, and testing. Are you looking for custom fabrication? Custom fabrication simply means that different people can offer you the solutions tailored to your needs. So, if you’re searching for Custom Fabrication Services manufacturers and suppliers, MULAN brings Custom Fabrication Services manufacturers and wholesalers close to you. Each Custom Fabrication Services listed above are subjected to inspection to make sure they are ready for trade. If you’re interested in buying Custom Fabrication Services, use the above list to discover the best wholesalers and manufacturers relating to Custom Fabrication Services.

What are pros and cons of Injection Molding Parts vs. CNC Machining Parts ?

Find the finest quality Blowing Moulds only at MULAN powered by world class manufacturers and suppliers across the globe. Blow molding is one of the most popular manufacturing process which uses hollow plastic molds. This process plays a vital role in the manufacturing of glass bottles. Blow molding process uses melted plastic and pouring it into a container made of plaster of Paris. It is mainly hollow from inside allowing air to pass through it. This process uses clamps by which molding are controlled and different shapes can be formed. MULAN is unique b2b platform connecting millions of buyers and suppliers with its exquisite quality controlling and a comprehensive range of products. Blowing molds at MULAN are made with premium quality raw material allowing durability, stability and enhanced product performance for longer use. Blowing molds are mostly used in the making of glass and other hollow fragile instrumentation.Connect with Blowing Moulds Manufacturers & Suppliers | MULAN"}" data-sheets-userformat="{"2":256,"11":3}" data-sheets-formula="=CONCATENATE("",RC,"")">

How is a insert injection molding parts made?

MULAN holds a broad range of plastic injection molds from authentic manufacturers in several sizes, models, and shapes to meet modern plastic injection molds and working challenges. The plastic injection are used to shape plastic by the use of rigid plastic molds. Plastic injection molds are commonly used for prototyping, and manufacturing processes. These molds allows fast manufacturing of with the help of modern aluminum type molds. We use high-tech industrial system to develop our plastic injection molds. With our intelligent engineering, cutting strategies our plastic injection molds allow fast paced and cost-effective manufacturing. We have a wide range of plastic injection molds that are to meet diverse manufacturing challenges of modern industries.MULAN is leading platform bridging millions of traders with its exquisite quality controlling and unmatchable product stability. Our plastic injection molds are perfectly designed to be used in various industries and to satisfy our buyers across the globe.

How can I choose a insert injection molding parts manufacturers ?

大理石无缝处理多用于地板,墙面缝隙建议采用金属边搭配,或凹槽边,既美 观又时尚,也减少墙面施工难度。 大理石的无缝处理可以直接提高大理石整个地板的观感,提高装饰的等级和美感。处理不好,石材间隙是日常使用中灰尘和污垢被掩盖的地方。每天清水留在裂缝中,石材变黑或被污染,产生各种污染源,引起石材病变、变黄、渗透等其他问题。 大理石无缝处理流程准备; 1、施工保护:施工前应保护施工现场木材单板、油漆面、壁纸、墙面盖及其他装饰工程。 2、竖向切割使大理石间隙干净,用吸尘器吸收垃圾,再次切割大理石袖子,使大理石间隙变平,用接近大理石颜色的大理石粘接剂填补接缝。 3、调整大理石粘合剂:使用大理石专用大理石粘合剂指定颜色,接近包装的大理石的颜色,避免颜色差异。 4、接缝补片:用调整后的大理石粘合剂填充接缝。大理石粘合剂完全凝固后会收缩一定程度,因此需要完全填充接缝。 5、切割研磨:专业大理石砂轮,研磨接缝高度,使大理石平台为水平面,提高美丽度,解决接缝间高度问题,防止接缝再次变黑。 大理石美缝处理注意事项;1、大理石接缝不要太大。开口处块的厚度应为0.3。2、切割后大理石和花岗岩须用吸尘器彻底清理,黑色接缝须特别清理。3、大理石胶粘剂与固化剂的比例应适度。确保从接缝到大理石粘合剂均的均匀分布,确保平滑的效果。4、填充大理石胶水时要留出足够的空间,使其与石头齐平。5、填充大理石粘合剂时要小心。不同颜色的石头接缝应“牢固”。工程完成后要留下伤痕!佛山MoCo Marble Tiles发展有限公司是家专业开采、加工、承接大理石装修一条龙产业链生产厂家,具有丰富的大理石加工、装修经验,承接过众多大型酒店安装石材,具有工厂供货、货源稳定,价格优惠等优势。

QUICK LINKS

mulan Cases & Services

CONTACT US