Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

what is sheet metal rapid prototyping | MULAN

Since established, MULAN aims to provide outstanding and impressive solutions for our customers. We have established our own R&D center for product design and product development. We strictly follow the standard quality control processes to ensure our products meet or exceed our customers' expectations. In addition, we provide after-sales services for customers throughout the whole world. Customers who want to know more about our new product sheet metal rapid prototyping or our company, just contact us.

Looking for the most appropriate sheetmetal fabrication?? You are at the right place. MULAN brings you a widestrange of different sheet metal fabrication by authentic suppliers andmanufactures from across the globe. Sheet metal fabrication involvesstructuring of metal by the process of bending, assembling and other metalmanipulating processes. This process is used in a wide array of industrialprocesses helping in manufacturing. The process can be used for casting,chipping, powder coating, powder metallurgy and welding. MULAN bring you the widest range ofsheet metal fabrication rightly designed to meet modern industrial requirementwith versatile applications. Explore our range now, we have fabrication sheetsmade up of highest quality steel to meet international quality standards. Oursheet metals are used in a variety of industries providing user cutting edgefunctionalities and durability to withstand extreme climatic conditions.

What are the benefits of MULAN sheet metal rapid prototyping ?

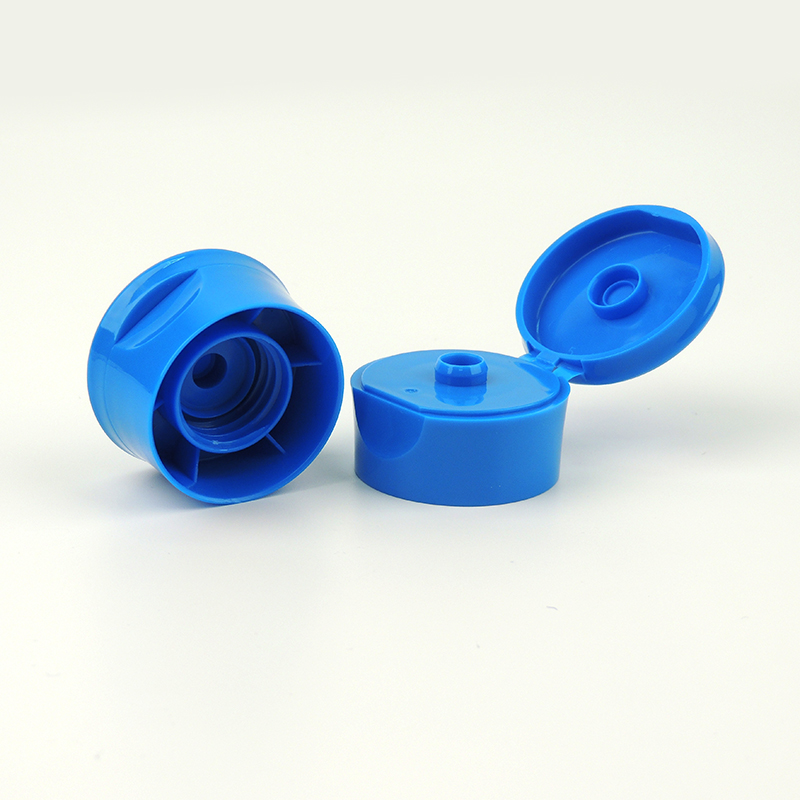

MULAN holds a broad range of plastic injection molds from authentic manufacturers in several sizes, models, and shapes to meet modern plastic injection molds and working challenges. The plastic injection are used to shape plastic by the use of rigid plastic molds. Plastic injection molds are commonly used for prototyping, and manufacturing processes. These molds allows fast manufacturing of with the help of modern aluminum type molds. We use high-tech industrial system to develop our plastic injection molds. With our intelligent engineering, cutting strategies our plastic injection molds allow fast paced and cost-effective manufacturing. We have a wide range of plastic injection molds that are to meet diverse manufacturing challenges of modern industries.MULAN is leading platform bridging millions of traders with its exquisite quality controlling and unmatchable product stability. Our plastic injection molds are perfectly designed to be used in various industries and to satisfy our buyers across the globe.

What are pros and cons of Injection Molding Parts vs. CNC Machining Parts ?

Want to buy a bulk of high-quality sheets for your collection? MULAN offers you the finest selection of top quality sheets, from the top suppliers. Our selection comprises of a large variety of all-purpose sheets usable in various areas like at hospitals, homes, hotels, or as disposable. The sheets in our range are made up of high-quality materials like 100% cotton, 100% polyester, 100% bamboo fiber, 100% silk, polyester/cotton, 100% polypropylene, polyester/bamboo fiber, and hemp/cotton fabrics that make the best sheets.We bring you a range of sheets in different patterns like plain dyed, printed, embroidered, and patchwork. Our featured sheets are designs to be artistic and durable even if extensively used. Our collection includes flat sheet, fitted sheet, and much more, in different styles like plain, stripe, jacquard, plaid, etc.MULAN is one of the most promising business to business platforms for suppliers and retailers. We’re devoted towards bringing buyers and sellers to our excellent trading solution, where they can join and trade. With our quality monitoring and inspection process, we make sure to feature quality pillow covers for the consumers.

How is a sheet metal rapid prototyping made?

Looking for the most appropriate Compression Molds?? You are at the right place. MULAN brings you the widest range of Compression Molds by official suppliers and manufacturers from across the globe. Compression molds are widely used by a wide range of industries including automobile, mechanical, and electronics products. Compression molds are used to compress products in the molds for precise manufacturing process. This process is cost effective and environmental friendly. It used matched metal molds that is closed mold manufacturing process. This process is nowadays being widely adopted by various automobile industries. MULAN is hub of traders across the globe connecting buyers, suppliers and manufacturers with its exquisite quality controlling, product definition, stability and strength. Compression molds at MULAN are prepared with world class raw material for increase durability and support.

How can I choose a sheet metal rapid prototyping manufacturers ?

无论是酒店、别墅、商场,还是家装时,总有一些地方需要做隔断,或者重新改造的,按照以往的做法,人们通常会选择使用红砖来做隔断墙,单红砖不仅重,而且还特别占地,不符合现代装修的风格。现在越来越多的人都开始用天然大理石做隔断,用大理石隔断墙不仅造型美观,文雅别致更能提升家装品质。 大理石隔断图片 下面我们来聊聊装修中适用大理石隔断墙的地方。1.隔断,把房间分隔室更很多空间的立面,能够使装修风格更加多变。与砖墙相比,隔断具有灵活、美观的特性。 隔断,顾名思义就是把空间隔开,区分空间,打破空间的固有格局,设计得当也起到了装饰和美观的作用,给家装设计加分。 用来做隔断的材料有许多,木材、玻璃、金属等都是常见的隔断材料,而大理石也可以用做隔断,天然的色泽和纹理让空间显得大方有质感。 2.玄关作为进入家庭的第一空间,决定了人们对它的第一印象,玄关的设计通常是将客厅分隔开,避免在公共区域上一览无遗,保护隐私,当然玄关的设计也是体现家庭风格的第一场所。客厅隔断设计可以发挥多种作用,在大户型中,客厅也相对宽敞,设计隔断则可以起到减少单调和空旷感的作用。 在客厅与通向家中其他区域的过道处设置隔断既可以区分空间也可作为装饰作用,当然客厅墙面也常常使用到隔断设计。 3.现代家居装饰卧室的设计不再仅仅是传统的床加高背景墙。床放在卧室的中央。大理石的一半背景墙被用作隔断,后面的空间被用作梳妆台或工作台。大理石是半背景墙的好选择之一,既方便又不失档次。 一物两用,将电视背景墙作为隔断。在小户型家庭中,为了在有限空间中做好区域的划分,常常会使用到隔断墙,高隔断则会让空间显得拥挤,所以半面墙隔断成为了不错的选择。当然无论什么样的户型,隔断设计都有它一定的作用。 4.由于厨房是一个生活气息强的地方,防水性和油烟都是需要考虑的问题,而大理石隔断在这两者上都十分符合使用在厨房,便于清洁。对于开放式厨房,隔断则常常用作区分空间。 5.卫生间在整个家居环境中属于水分较大的空间,所以干湿分离也是十分有必要的,大理石作为卫生间隔断,既可以区分淋浴间和梳妆间,且材质适合作为防水隔断。 大理石隔断运用的好,不仅丰富家装设计功能的实用性,拓展和充分利用空间,又起到装饰作用,且大理石的天然质感,提升家装档次。 文章链接来源www.slfsy.com

QUICK LINKS

mulan Cases & Services

CONTACT US