Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

best injection molding parts at Wholesale Prices | MULAN

Always striving toward excellence, MULAN has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. best injection molding parts Today, MULAN ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product best injection molding parts and our company by directly contacting us.The product is of highest quality and manufactured under strict quality control system.

China Mulan Manufacture Group is an ISO 9001-2015OEM plastic molding parts manufacturer, specializing in the production of plastic injection molding, rotational molding, blow molding and other customized plasticmolding parts. We actively provide one-stop technical support and manufacturing services for custom plastic parts buyers in various industries around the world.

We have a professional injection molding technical team, with more than 8 engineers specializing in injection mold design, to provide one-stop service from product design, mold tools, technical support, consulting services, sample manufacturing, mass production, packaging and shipping.

We have rich manufacturing experience, and from North America, the United States, Canada, Germany, France, Italy, Spain, the Netherlands and other countries in a variety of industry manufacturers, wholesalers, trading companies and agents long-term cooperation, we are confident to become your most reliable OEM custom plastic molding parts supplier.

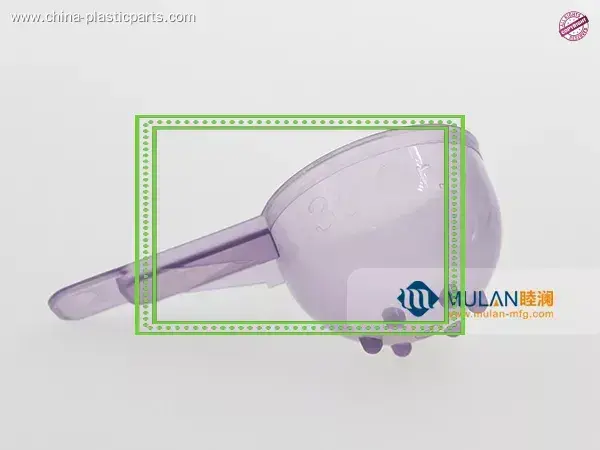

name | PE injection molded tableware |

color | white,black,green,nature,blue,yellow,etc(Customized) |

material | ABS,PC,PP,PU,PE,UPE,PTFE,PA6,PA66,etc |

shape | customizedyour drawing or on-demand your needs |

free sample | available |

advantage | One-stop manufacturing services |

Application field | Various plastic injection molded parts for various industrial and automotive applications |

lead time | 25-35 days for mould,plastic products according to quantity |

Terms of payment | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

Certification: | RoHS, ISO9001-2015 |

About the mould

Plastic molds have a very important position in industrial systems, and have developed very rapidly in the last 30 years, occupying a dominant position. The high-quality manufacture of precision injection molds is the basis for the wide application of a product. When the molten plastic is injected into the mold cavity by a pressure screw, a series of activities such as filling, cooling, solidification, heat preservation, shaping, and ejection are performed. Finished in the mold, and finally get the product we are satisfied with.

And a high-quality mold must not only meet the needs of customers in terms of dimensional accuracy, but also fully consider the quantity demand of the product, so as to ensure that high-quality injection molding parts can be manufactured in batches stably within the effective life of the mold.We have a strong mold manufacturing factory, through the use of UG, Pro/ E, SolidWorks, CAD and other 3D modeling software design high precision mold skills.

Through the advanced large-scale CNC machining center 10, CNC engraving machine 18, EDM spark forming machine and precision wire cutting machine manufacturing molds.

We will carry out a comprehensive CMM inspection on all mould products to ensure that the mould is put into production line with high precision.

Capability

1.OEM/ODM orders are acceptable.

2. Plastic molding parts for customized LOGO.

3. 24H*7 online technical team.

4. Experienced technical experts.

5. Advanced manufacturing equipment.

6. English sales team barrier-free communication.

7. Online Free technical support

QUICK LINKS

mulan Cases & Services

CONTACT US