Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

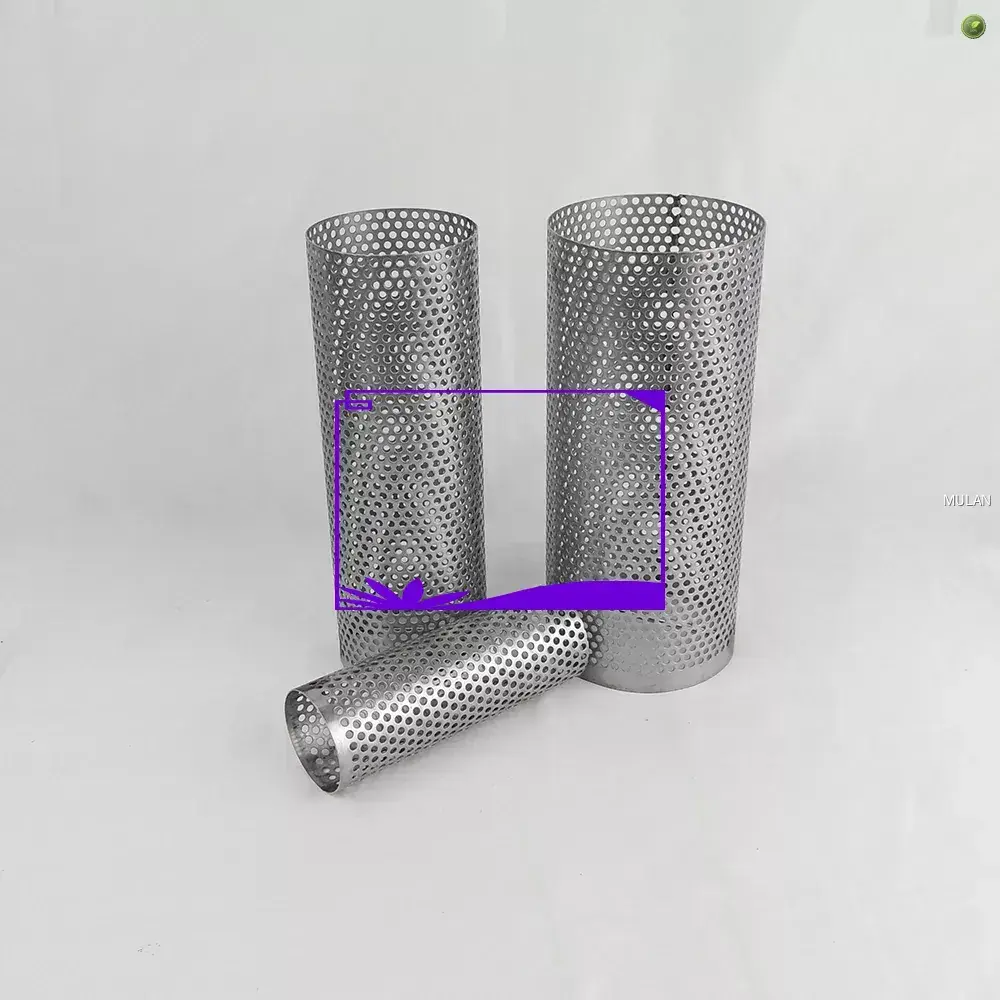

efficient custom sheet metal parts maker | MULAN

Guided by scientific and technological innovation, MULAN always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. custom sheet metal parts If you are interested in our new product custom sheet metal parts and others, welcome you to contact us.The design of MULAN custom sheet metal parts combines these two attractive characteristics, aesthetics and user-friendliness.

At Mulan Manufacturing Group, we use high powered lasers (4kW to 12kW) to create incredibly accurate cuts on materials such as 6061 aluminum, mild steel, copper, stainless steel, brass, laser cut acrylic, wood and more.

Whether yoursquo;re a small business owner in your garage, or a manufacturer that needs 100,000 parts a week, we help turn your designs into a reality by providing you fast, affordable, and accurate

About MULAN

Product Introduction

Company Advantages

Frequently Asked Questions about quality plastic molding

using industrial laser cutting.

Looking for a reliable, quick-turn supplier of machined plastic and metal components? With hundreds of CNC machines, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Mulan, our AS9100-certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

CNC milling service can be applied to a wide variety of materials, including metal, plastic, and wood. Different milling are needed for milling metal and wood. According to the types of machined part materials, certain maintenance and safety precautions may be required for the milling. Here are some common materials for CNC milling manufacturers below. If the material you required is not listed in the table, please contact us.

Material | Available Types amp; Grades |

Aluminum | Aluminum 2024 Aluminum 5052 Aluminum 5083 Aluminum 6063 Aluminum 6061 Aluminum 6082 Aluminum 7050 Aluminum 7075 |

Brass/Bronze | Brass C360 Brass 260 C932 M07 Bearing Bronze |

Copper | Copper C110 Copper 101 |

Steel | Alloy Steel 4130 Alloy Steel 4140 Mild Steel 1018 Mild Steel A36 |

Stainless Steel | Stainless Steel 17-4 Stainless Steel 18-8 Stainless Steel 303 Stainless Steel 304/304L Stainless Steel 316/316L Stainless Steel 416 Stainless Steel 420 |

Titanium | Titanium Grade 2 Titanium Grade 5 |

Plastics | ABS Nylon POM PEEK PMMA PTFE Polystyrene Polyethylene Polycarbonate |

What is CNC machining?

Computer numerical control(CNC) could be a powerful machine which fixed and rotated the raw material rod on it's driving headstock, to remove the material by means of relative movement between various cutting tools and raw material rod. Advanced programming software which optimized machine setting, cutting time, surface finish, and fine turning tolerance is used to control a CNC turning milling machine according to the instructions of clients' CAD drawing file.

Our CNC production lines are not only to manufacture turning part workpieces and prototypes, but also to build molding tools, which are to be used for plastic injection molding or die casting.

Types of CNC Production Lines

At Mulan, we offer our clients with varies of CNC services including turning, milling, drilling, grinding and much more. Our engineer can use precision manufacturing production lines such as 3, 4 and 5 axis machine centers to make parts base on clients' 2D and 3D CAD drawings. CNC Hobbing is mainly used for cutting gears, splines, and key slots. CNC plasma cutters and CNC water jet cutters are used for profile cutting of the sheet material.

No matter your are looking for precision plastics, aluminum, stainless steel parts manufacturing, our production lines are capable of wide range of precision parts made of plastics or metals. Contact our team to get a free quote and to discuss which manufacturing process is the most efficient and suitable one for your project.

From CAD drawing to machined parts

We are capable of making partsensp;from the print via CAM software, CNC turning and milling machines.

1.) Checking and confirming your CAD drawings

Once order confirmed, 2D and 3D CAD drawings well received from clients. Till today, more than ten thouthand CAD drawings been checked and confirmed before production to feedback if there are any problems opening the drawing files or other obvious issues:

a.) To receive a "no quote" if the part is outside Mulan's capabilities.

b.) To receive suggestions for ways to improve design for production, also to reduce cost without losing functionality.

c.) To receive a quote with the shortest possible lead time for delivery.

2.) Programming

Our professional CNC programmers use PC-based CAD/CAM software Mastercam for fast and efficient turning/milling. During this stage, we keep looking for better way to optimize design for production.

3.) Production

Following instruction of CAM software, step by step well manufactured via CNC milling machine centers while our production lines are capable of 2 axis, 3 axis, 4 axis and 5 axis CNC machines. From simple dowel pins, shaft to complex turning-milling parts, we have got you covered.

QUICK LINKS

mulan Cases & Services

CONTACT US