Over the years, MULAN has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. injection molding parts factories If you are interested in our new product injection molding parts factories and others, welcome you to contact us.For MULAN, a good product should be supported with a better after-sale service.

## Advantages of PP Injection Molding for Power Tool Housings

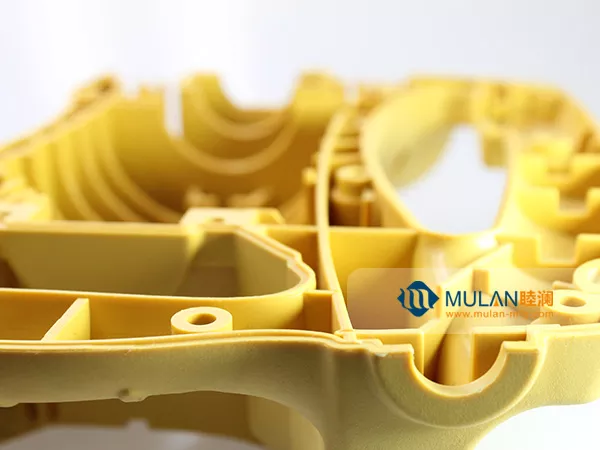

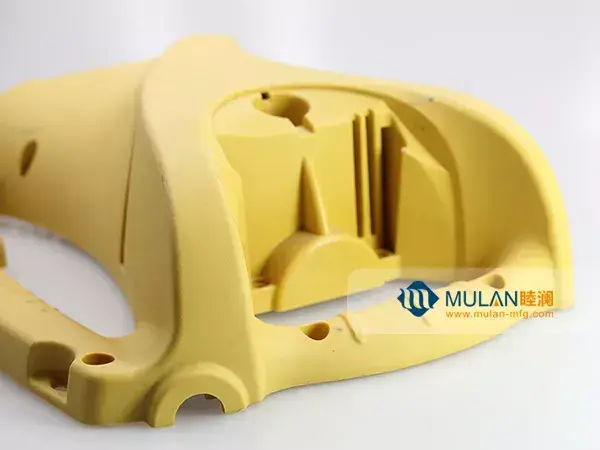

- Lightweight and durable properties of PP molded power tool housings

- Resistance to impact, heat, and chemicals

- Cost-effectiveness and efficiency in mass production

## Applications and Examples

- Diverse range of power tools that utilize PP injection molded housings

- Examples of well-known power tool brands using PP injection molding for their products

## Conclusion

- Recap of the importance and benefits of PP injection molding for power tool housings

- Emphasis on the role of advanced technology and precision in the manufacturing process

- Encouragement for

About MULAN

Mulan Group specializes in the manufacture of customized parts. It has been engaged in the customized production of plastic and metal parts for more than 18 years. Mulan Group uses advanced processing equipment and scientific quality management system to provide global suppliers with one-stop customized plastic and metal custom parts production solutions. Mulan Group provides a cost-effective one-stop supply service with an efficient sales team, reasonable low-cost quotation and strong manufacturing resources.

Rich production experience allows Mulan Group’s services to meet the products of various industries. Mulan Group has participated in many important product development and manufacturing to understand the use characteristics and requirements of different products. In other words, only a brief description of the customer, the production plan and the actual cost of the product can form a formal report.

Mulan Group currently owns 2 manufacturing companies and holds 3 processing plants. Its business scope includes: CNC Machining Service, Sheet metal Fabrication, Rapid Prototyping, Plastic injection molding service, mould tools, etc. An experienced team of engineers and an efficient sales team provide quick feedback to all production project queries for global buyers.

Product Information

Company Advantages

500+ company personnel, professional R&D team.

Frequently Asked Questions about high quality plastic molding

Q:What are the disadvantages of blow moulding?

A:Blow molding has many limitations due to the molding principle, so there are a few points that should be paid attention to when designing blow molding products:

● Only limited to hollow structural parts.

● The wall thickness is thin and the strength is low.

● By adding other materials in the multilayer part, the effect of blocking sound and heat sources is increased. (So not recyclable)

● A second trimming is required to remove burrs and excess material.

● Only for thermoplastics

Q:Where is blow moulding used?

A:Blow molding is widely used in the production of hollow structure products, such as: water bottles, oil drums, chemical turnover barrels, floats, medical reagent bottles, etc. Injection blow molding is suitable for small container production, and stretch blow molding is suitable for medium and large-volume container products. However, the surface effect of injection blow molded products is better than stretch blow molding, and can be highly transparent and flat. Drinking water bottles are the most typical injection blow molding.

Q:Is blow moulding expensive?

A:Blow molding will be more cost-effective than injection and rotational molding.

Generally speaking, the production cost of a product needs to refer to several factors, such as part structure design, product quantity, product material selection, and product application functionality. After a comprehensive analysis, we choose the most reasonable cost manufacturing process. Blow molding materials are relatively small, but for hollow structure parts, the structure is not complicated. When mass production is required, blow molding must be cheaper and more efficient than other plastic molding processes.

Q:What is the Difference Between Blow Molding and Injection Molding?

A:The main difference between injection molding and blow molding is the types of products that can be produced. Generally, blow molding is the manufacture of hollow containers, such as bottles, pots, barrels and so on. There is no injection port on the surface, Injection molding is used to produce solid parts. The plastic granular material is first melted, and then injected into a closed mold under high pressure for shaping. There will be traces of the injection port on the surface.

further exploration and research in the field

![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660