Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

What is general plastics? | MULAN

General plastics mainly include polyethylene, polypropylene, polyvinyl chloride, polystyrene, ABS, etc., whose output accounts for more than 90% of the entire plastic production.

Polyethylene (PE)

Polyethylene is the most productive variety in the plastics industry. Polyethylene is opaque or translucent, light crystalline plastic, with excellent low temperature resistance (minimum up to -70 ~ -100℃), electrical insulation, good chemical stability, resistance to most acid and base erosion.

Polypropylene (PP)

Polypropylene is a colorless semi-transparent thermoplastic, odorless, non-toxic and lightweight. It has the advantages of cooking resistance and corrosion resistance. Strength and rigidity are better than polyethylene.

Polypropylene has the advantages of low price, good comprehensive performance, easy processing and wide application. Polypropylene can be made into furniture, tableware, toys and other daily necessities, and is often used to make steering wheels, dashboards, bumpers and other car parts.

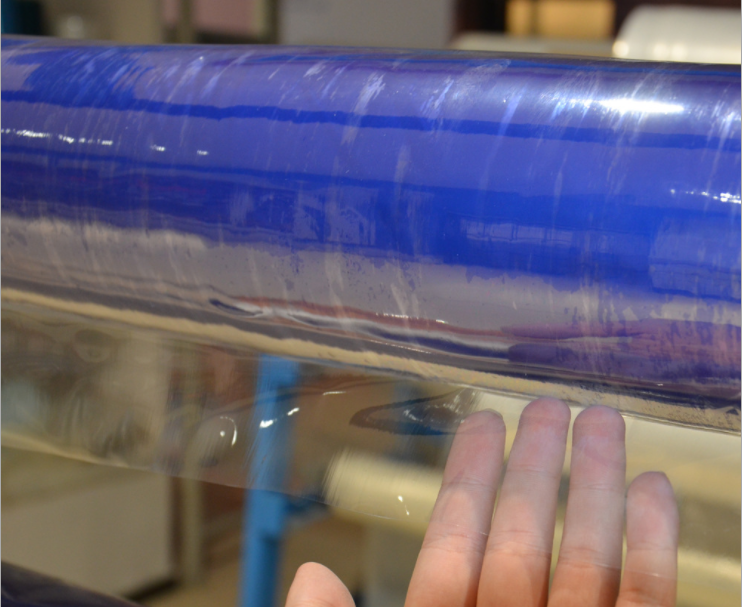

Polyvinyl chloride (PVC)

PVC can be made into both hard products and soft products, and is widely used.

Including plastic cloth, shed cloth, packaging materials, water pipes, doors and Windows, boxes, leather bags, sofa sports shoes, car cushions, wire skin and so on.

Polystyrene (PS)

Divided into general purpose polystyrene (GPPS), high impact polystyrene (HIPS), extensible polystyrene (EPS)

GPPS is odorless, tasteless, non-toxic, hard and transparent.

It is mainly used for daily crystal, stationery, lamps, indoor and outdoor decorations, cosmetics containers, fruit bowls, instrument shells, seed covers and food packaging.

HIPS has good stiffness, good coloration and good impact resistance.

Mainly used in packaging materials, such as food, cosmetics, daily necessities, mechanical instruments and stationery packaging; In addition, it can also be used for electrical accessories, buttons, auto parts, medical equipment, furniture, toys and so on.

EPS can be made of foam plastic, with good sound insulation, heat insulation, shock absorption properties.

About MULAN

QUICK LINKS

mulan Cases & Services

CONTACT US